-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

What is an Aerogel Blanket and How Does It Work?

An Aerogel Blanket is a remarkable insulation material. It combines lightness with exceptional thermal resistance. Engineers and scientists created it to tackle extreme temperature challenges. Its unique structure allows it to trap air effectively. This leads to superb insulation properties.

What is fascinating about Aerogel Blankets is their versatility. They are used in various applications, from space missions to construction. The material is so light that it can float on air. Despite this, it provides substantial insulation. However, it can be delicate. This raises questions about durability and long-term effectiveness.

Aerogel is not just about high-tech jargon. Its benefits can sometimes be overshadowed by its challenges. Users must consider how to handle and maintain it. Few materials combine beauty and functionality like Aerogel Blanket. Yet, it requires careful thought and planning for optimal use.

What is Aerogel and How is it Made?

Aerogel is a remarkable material known for its unique properties. It is often referred to as "frozen smoke" due to its translucent appearance and extremely low density. Aerogel is mostly composed of air, with about 90-99% of its volume being empty space. This structure gives it excellent insulating properties, making it valuable in various industries.

The production of aerogel begins with a gel phase, typically derived from silica, alumina, or polymeric materials. A key aspect is the sol-gel process, where a liquid solution transforms into a gel. Once the gel is formed, supercritical drying removes the liquid without collapsing the structure. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers, aerogel can reduce thermal conductivity to as low as 0.013 W/mK. This is significantly lower than traditional insulation materials.

Despite its stellar performance, aerogel has its challenges. Its fragile nature makes it difficult to handle and work with in certain applications. Additionally, the production process can be energy-intensive and costly. While many manufacturers are researching ways to improve the affordability and durability of aerogels, questions about scalability in broader applications persist. As demand grows, finding a balance between performance and practicality remains a key issue for the industry.

What is an Aerogel Blanket and How Does It Work?

| Attribute | Description |

|---|---|

| Material | Silica Aerogel |

| Density | 0.1 - 0.3 g/cm³ |

| Thermal Conductivity | 0.013 - 0.020 W/m·K |

| Applications | Insulation, aerospace, oil spill cleanup |

| Advantages | Lightweight, high thermal resistance, non-toxic |

| Manufacturing Process | Sol-gel process followed by supercritical drying |

| Moisture Resistance | Good; can be treated for water repellency |

The Structure and Properties of Aerogel Blankets

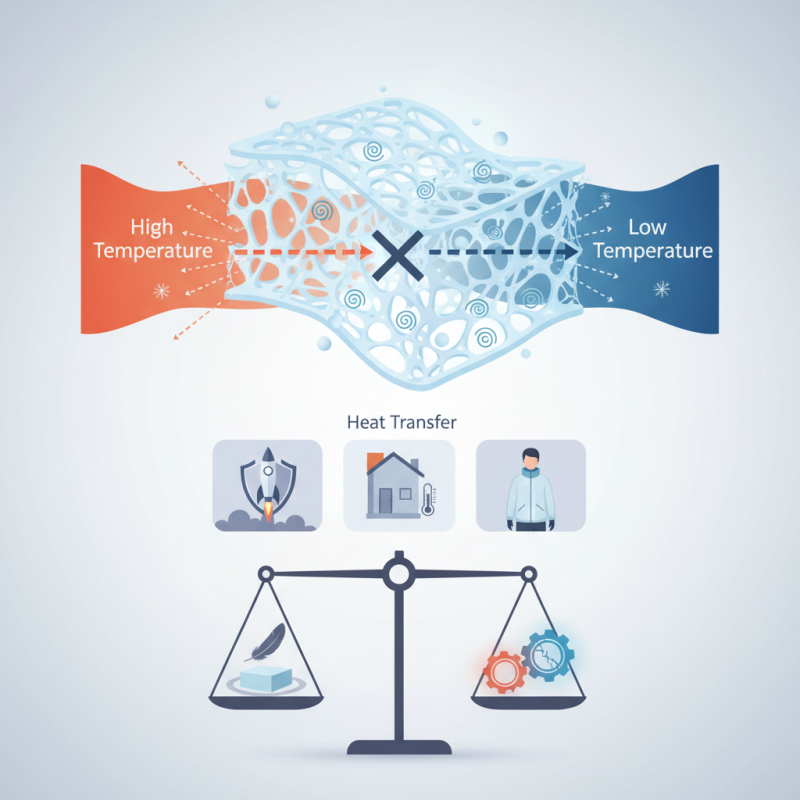

Aerogel blankets are fascinating materials known for their unique structure and impressive properties. These blankets consist primarily of air, making them incredibly lightweight yet incredibly effective insulators. The porous nature of aerogel allows it to trap air in tiny pockets, which reduces heat transfer. This is why they are often used in applications requiring thermal insulation, like space missions and extreme temperature environments.

When examining the structure of an aerogel blanket, you'll notice its sponge-like quality. It comprises a network of silica or carbon particles, resulting in a low density. This indicates that while aerogels are fragile, they hold incredible thermal resistance. The visual contrast between its slim form and substantial insulating capabilities often surprises people.

Tips: When using or handling aerogel blankets, handle them gently. They can break easily under pressure. Store them in a dry, cool place to maintain their integrity. Always keep in mind that while they excel in insulation, their durability can be a concern. Regular checks can help you identify any potential wear and tear.

How Aerogel Blankets Provide Thermal Insulation

Aerogel blankets are fascinating materials that offer remarkable thermal insulation. They are made from a gel, where the liquid component is replaced with gas, creating a lightweight structure. This unique composition allows aerogels to achieve some of the lowest thermal conductivities known. In fact, studies indicate that aerogels can have thermal conductivities as low as 0.013 W/m·K, making them incredibly effective in minimizing heat transfer.

These blankets are particularly useful in extreme environments. For instance, they are used in space missions and for building insulation in ultra-cold areas. Their high-performance insulation effectively reduces energy loss. This can lead to significant savings, as homes can lose up to 30% of their heating energy through walls and roofs. Aerogel blankets can dramatically decrease this percentage.

Tips: When using aerogel blankets, consider proper installation practices. Even the best materials can falter if not applied correctly. Also, regularly inspect your insulated areas for any signs of wear or moisture. Keeping aerogel clean is important, as dust accumulation can affect performance. Always ensure your aerogel blankets are suited for the specific temperature ranges of your environment.

Applications of Aerogel Blankets in Various Industries

Aerogel blankets are redefining insulation in various fields. Their light weight and delicate structure offer unique benefits. In the aerospace sector, these blankets are crucial. They provide superior thermal insulation for spacecraft, protecting sensitive equipment from extreme temperatures. They help maintain functionality during launch and re-entry, which is vital for mission success.

In construction, aerogel blankets are revolutionizing energy efficiency. They can be easily integrated into walls and roofs. This offers remarkable thermal performance while minimizing space. Industrial applications also benefit from these blankets. They protect pipelines and vessels, preventing heat loss in factories. However, manufacturers still face challenges in mass production. The high cost remains a barrier for widespread adoption.

Some users may find aerogel blankets difficult to handle. Their fragile nature can lead to wear and tear. Proper training is essential for effective use. Testing in real-world scenarios is necessary to ensure reliability. These aspects require attention as the industry seeks to capitalize on aerogel technology.

Comparing Aerogel Blankets to Other Insulation Materials

Aerogel blankets stand out in the realm of insulation materials. They are incredibly lightweight and have a unique structure that traps air. This results in remarkable thermal insulation properties. When compared to traditional materials like fiberglass or foam, aerogel blankets provide superior insulation with much less weight. Their ability to resist heat transfer makes them ideal for extreme conditions.

However, aerogel blankets are not without challenges. They can be fragile and may require careful handling. Unlike thicker insulation options, aerogel blankets can be thinner and still achieve high R-values. This can be beneficial in applications with space constraints. Nevertheless, the cost can be a limiting factor for some projects.

Different insulation materials have their pros and cons. Fiberglass is more affordable but heavier and less efficient. Foam, while effective, can have environmental impacts. Importantly, the choice often depends on specific needs. Each material has scenarios where it excels or falls short. This complexity makes selecting the right insulation a thoughtful process.

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy