-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

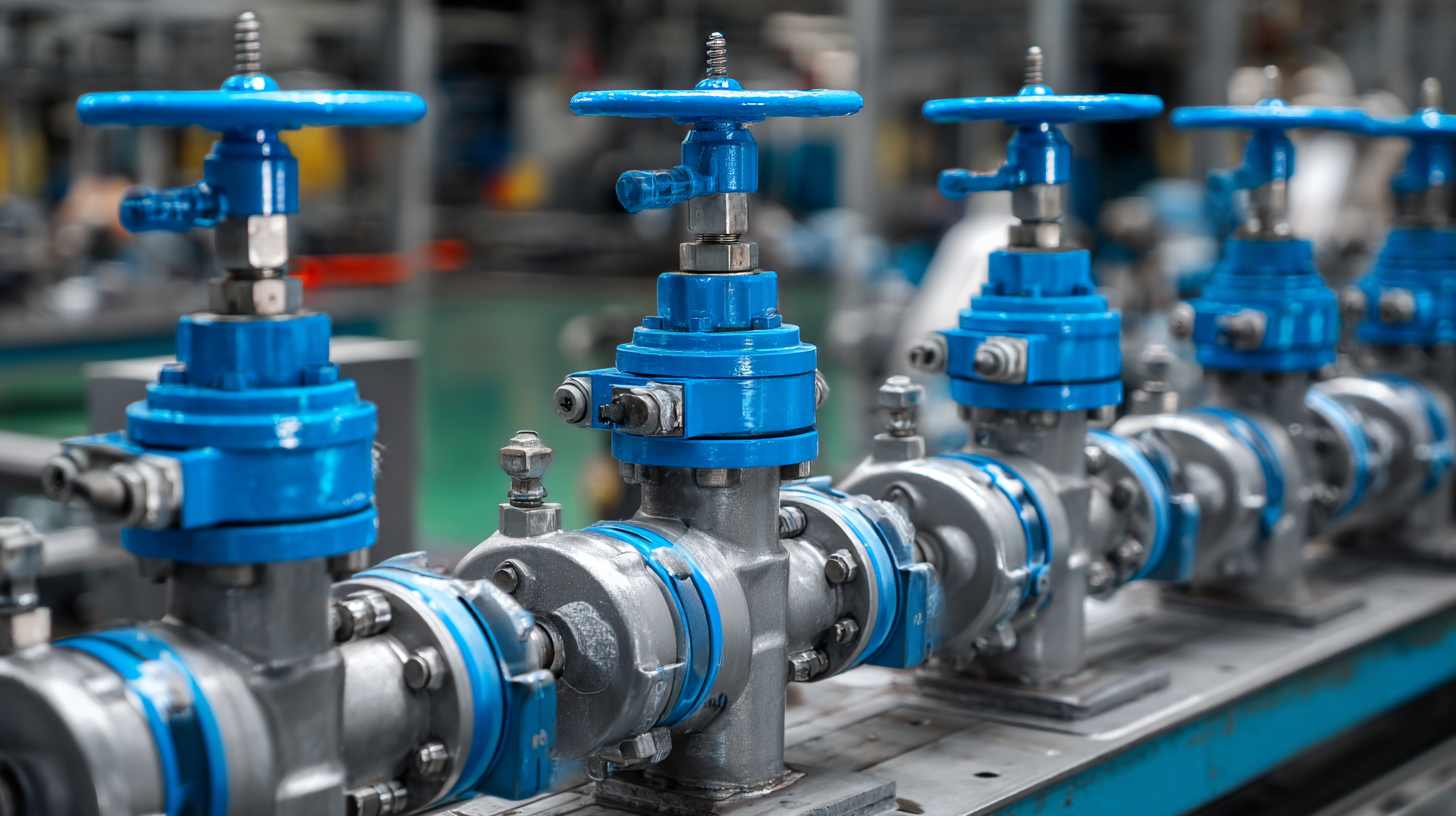

Understanding the Benefits of Automatic Control Valves in Modern Industrial Applications

In the rapidly evolving landscape of modern industrial applications, the significance of Automatic Control Valves cannot be overstated. These sophisticated devices play a crucial role in optimizing process efficiency and maximizing operational safety across various sectors, including oil and gas, water treatment, and manufacturing. According to a report by Transparency Market Research, the global automatic control valve market is expected to grow significantly, projected to reach $6.5 billion by 2027, driven by increased demand for automation and improved energy efficiency. The integration of Automatic Control Valves not only enhances the precision of fluid control but also minimizes downtime through advanced monitoring and feedback mechanisms. This article will explore the myriad benefits of Automatic Control Valves, shedding light on their vital contributions to industrial automation and sustainability in contemporary applications.

Overview of Automatic Control Valves and Their Functionality

Automatic control valves play a pivotal role in various modern industrial applications, functioning as crucial components that regulate fluid flow and maintain system efficiency. These valves automatically adjust the flow rate based on feedback from the system, ensuring optimal performance and reducing the risk of overpressure or underflow scenarios. By precisely controlling the flow and pressure, they enhance operational safety while minimizing energy consumption and waste.

Automatic control valves play a pivotal role in various modern industrial applications, functioning as crucial components that regulate fluid flow and maintain system efficiency. These valves automatically adjust the flow rate based on feedback from the system, ensuring optimal performance and reducing the risk of overpressure or underflow scenarios. By precisely controlling the flow and pressure, they enhance operational safety while minimizing energy consumption and waste.

In the context of advancements in laboratory medicine, the integration of automatic control valves with new technologies, such as microfluidic systems, exemplifies the shift towards more sophisticated and efficient methodologies. These innovations streamline complex processes, allowing for quicker and more accurate diagnostic results. By automating fluid management, laboratories can significantly enhance throughput and reproducibility in analysis, which is critical for clinical applications.

Tips:

1. When selecting automatic control valves, consider the specific requirements of your application, including fluid type, required flow rates, and pressure ratings, to ensure optimal performance.

2. Regular maintenance and calibration of control valves can prevent system failures and prolong their lifespan, ultimately saving time and resources in industrial operations.

Key Advantages of Implementing Automatic Control Valves in Industries

The implementation of automatic control valves in various industrial applications is transforming operational efficiency and safety. According to a report by Grand View Research, the global control valves market size was valued at USD 9.56 billion in 2020 and is expected to grow at a CAGR of 6.2% from 2021 to 2028. This growth underscores the rising demand for automation, particularly in industries such as oil and gas, chemicals, and water treatment. Automatic control valves enhance process consistency and reduce manual errors, which not only streamlines operations but also minimizes the risk of system failures.

Moreover, automatic control valves significantly contribute to energy savings and resource optimization. A study published by the International Energy Agency (IEA) indicates that optimizing valve control can lead to energy reductions of up to 30% in industrial processes. These valves allow for precise regulation of flow, pressure, and temperature, making it easier for industries to maintain operational parameters while reducing wastage. As industries increasingly adopt automation technologies, the integration of automatic control valves is proving essential for meeting both production goals and sustainability targets.

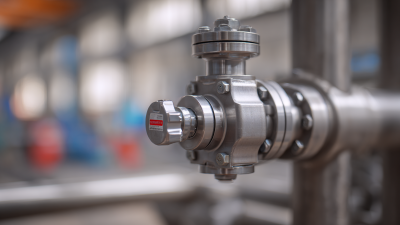

Applications of Automatic Control Valves in Various Industrial Sectors

Automatic control valves play a crucial role across various industrial sectors by optimizing fluid and gas flow through automated mechanisms. In the HVAC industry, these valves help maintain precise temperature and pressure control by responding to changes in system conditions, thus ensuring energy efficiency and comfort. In water treatment facilities, automatic control valves are vital for managing flow rates and pressures, improving the reliability of water distribution and enhancing overall system performance.

Tips: When implementing automatic control valves, consider the specific requirements of your system, including the type of fluid being controlled, the range of operating pressures, and the desired response time. Proper sizing and selection of these valves can significantly reduce maintenance costs and downtime.

In the oil and gas sector, automatic control valves enhance safety and efficiency during the extraction and transportation processes. They can automatically adjust to variations in flow, temperature, and pressure, minimizing the risk of leaks and spills. Additionally, in pharmaceutical manufacturing, these valves ensure the consistent delivery of fluids, critical for maintaining product quality and compliance with stringent regulations.

Tips: Regular maintenance and calibration of automatic control valves are essential to prevent unexpected failures. Schedule periodic inspections and always refer to the manufacturer’s guidelines for optimal performance.

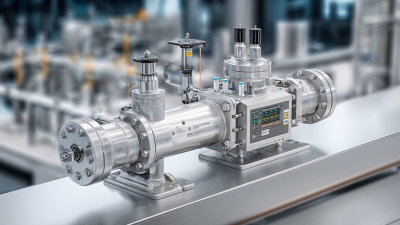

The Role of Automatic Control Valves in Enhancing System Efficiency

Automatic control valves play a crucial role in enhancing system efficiency across various industrial applications. According to a report by MarketsandMarkets, the global automatic control valve market is projected to reach USD 5.73 billion by 2025, growing at a CAGR of 5.4% from 2020. This growth reflects the increasing demand for automation in industries like oil and gas, water treatment, and power generation, where precise control of flow and pressure is essential for optimal operations.

These valves utilize advanced technologies, including digital monitoring and smart sensors, to facilitate real-time adjustments based on system demands. This capability significantly reduces energy consumption and waste. A case study from the American Society of Mechanical Engineers indicated that manufacturing facilities incorporating automatic control valves into their systems achieved efficiency improvements of up to 30%. Additionally, these valves also minimize response times, enhancing overall system reliability and performance, ultimately leading to reduced operational costs and increased productivity in modern industrial settings.

Future Trends and Innovations in Automatic Control Valve Technology

The field of automatic control valve technology is poised for significant advancements in the coming years, driven by a robust increase in market demand. By 2032, the control valve market is predicted to witnesses a remarkable growth from USD 7.8 billion in 2024 to USD 15.5 billion, showcasing a compound annual growth rate (CAGR) of 9.1%. This growth trajectory is indicative of the rising need for enhanced automation in diverse industrial applications, reflecting a broader shift towards smarter, more efficient manufacturing processes.

Future trends in automatic control valve technology will likely focus on connectivity and sensor integration, facilitating real-time monitoring and precise control over fluid dynamics. Innovations such as artificial intelligence and machine learning are expected to play a pivotal role in optimizing valve performance and reliability. As industries become increasingly reliant on data-driven solutions, automatic control valves will evolve to meet the demands of modern infrastructure, emphasizing not only control efficiency but also sustainability and energy savings. The ongoing technological enhancements promise to transform how industries approach flow regulation, ultimately addressing the complexities of contemporary industrial challenges.

Understanding the Benefits of Automatic Control Valves in Modern Industrial Applications

This chart illustrates the adoption rates of automatic control valves in various industrial sectors over the years, highlighting the growing importance of these technologies.

Related Posts

-

The Future of Smart Automation in Best Automatic Valves

-

Innovative Solutions for Optimal Performance with Best Flow Control Valves

-

Understanding the Importance of Level Control Valves in Modern Industrial Applications

-

Unlocking Efficiency: The Advantages of the Best Water Pressure Control Valve for Your Home

-

The Ultimate Guide to Choosing the Best Water Pressure Reducing Valve for Optimal Performance and Savings

-

Ultimate Pressure Control Valve Maintenance Checklist for Optimal Performance

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy