-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

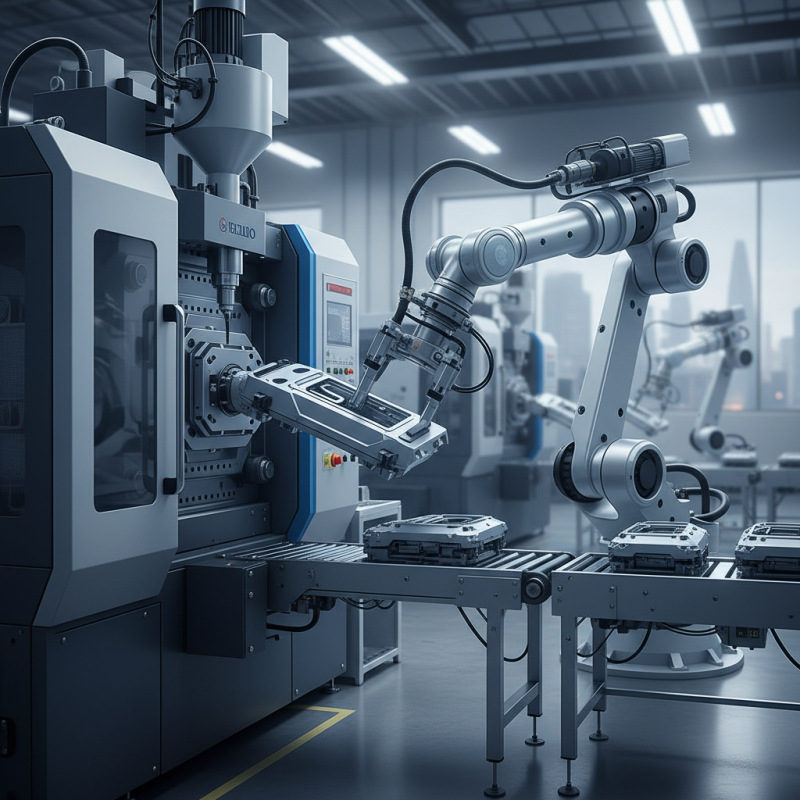

Top Benefits of Using Injection Molding Machine With Robot?

The manufacturing industry is evolving rapidly, and one significant trend is the adoption of the Injection Molding Machine With Robot. According to a report by Grand View Research, the global market for injection molding machines is projected to reach $13 billion by 2025. This growth is fueled by the demand for automation and efficiency in production processes. Industry expert Dr. Sarah Thompson states, "Integrating robotics with injection molding significantly reduces cycle times and increases precision."

Once considered a luxury, the Injection Molding Machine With Robot is now a necessity. Companies are realizing the value of automation in enhancing productivity. Reports indicate that firms implementing robots see a 20% increase in manufacturing output. However, integration can be challenging. Not all companies have the infrastructure needed for such machines. Understanding operational requirements is crucial for a successful transition.

Despite the advantages, some businesses hesitate. High initial costs and technical challenges can seem daunting. It’s vital to weigh the benefits against potential setbacks. The Injection Molding Machine With Robot offers an opportunity for innovation, but companies must also prepare for the complexities involved. Embracing this technology could define the future of manufacturing.

Benefits of Injection Molding Machines with Robotics in Manufacturing

Injection molding machines integrated with robotics are revolutionizing manufacturing. These advanced systems enhance productivity. A recent industry report suggests that incorporating robotics can boost output by 30% to 50%. Additionally, cycle times are significantly reduced, leading to faster production rates.

Automation in injection molding also improves precision. Robots can handle repetitive tasks with higher accuracy than human operators. This reduces the risk of defects and waste. Research indicates that manufacturers using robotic systems report a decrease in scrap rates by 15% or more. This not only saves materials but also lowers costs in the long run.

Tips: To maximize the benefits of robotics in your injection molding process, consider training staff on new technologies. Engaging your team can uncover areas for improvement and enhance overall efficiency. Regular maintenance and upgrades to robotic systems can prevent costly downtimes. Continuous evaluation of processes is crucial for staying competitive.

Increased Production Efficiency through Automation and Robotics Integration

Automation and robotics integration in injection molding has transformed production processes. According to recent industry reports, factories can achieve up to 30% faster cycle times with robotic arms operating injection molding machines. This speed enhances productivity significantly and reduces manual labor needs. Automation not only streamlines operations but also minimizes human error, leading to consistent quality in production.

Robots can work alongside molding machines to handle tasks like part removal and assembly. Studies show that the adoption of robotics can reduce labor costs by about 20%. However, integrating robots isn't without challenges. Initial setup costs can be high, and staff may require training to operate new systems effectively. There are also concerns about machine maintenance and downtime, which can impact overall efficiency.

While automation offers compelling benefits, manufacturers need to evaluate their specific needs. Not all production lines will benefit similarly from robotic integration. A detailed analysis is essential to ensure that the transition is not only cost-effective but also aligns with long-term goals. This reflection can guide organizations in making the right decisions for their manufacturing strategies.

Enhanced Precision and Quality Control in Molding Processes

The integration of robotics in injection molding processes significantly enhances precision and quality control. Automated systems allow for consistent placement of molds and materials. This step reduces variations during the injection process, ensuring each part is identical to the last. When robots handle the entire molding cycle, errors caused by human intervention are minimized. This results not only in higher quality products but also reduces the need for rework and additional inspections.

Additionally, precision in molding contributes to reduced material waste. Machines can be programmed to use exact quantities of plastic, minimizing excess. However, achieving this level of precision can require initial trials and adjustments. Companies must be prepared for some setbacks as they optimize their systems. Regular maintenance and calibration of both the molding machine and robot are also vital. While automation reduces certain errors, it can introduce new challenges, like requiring skilled operators for monitoring and troubleshooting.

Robotic systems can adapt to different molding requirements quickly. They can take on multiple tasks, such as loading and unloading, which can streamline production. Nevertheless, there’s a learning curve involved in programming these robots effectively. Companies exploring these technologies must invest time in training staff. Balancing automation with human oversight can lead to striking improvements in overall workflow.

Reduction of Labor Costs and Improved Safety in Production Lines

The integration of robots with injection molding machines significantly reduces labor costs. A recent industry report indicates that automation can cut labor expenses by up to 30%. This is crucial for manufacturers looking to improve their bottom line. With robots handling repetitive tasks, fewer workers are needed on the production floor. This also enables existing staff to focus on higher-value activities, promoting efficiency.

Moreover, enhanced safety is a pivotal benefit of this technology. Robots take on dangerous tasks, minimizing injury risks for human workers. According to OSHA, workplaces using robotic systems have seen a 40% reduction in workplace accidents. The automation of material handling and assembly operations protects employees from hazardous environments. However, not all manufacturers have embraced this trend. Some might hesitate to invest in initial setup costs. Yet, the long-term gains often outweigh these initial expenses.

Ultimately, the push for improved safety and reduced labor costs highlights the potential of robotics in manufacturing. Further research is essential to fully grasp how effective these systems can be in different contexts. Balancing costs and benefits remains an ongoing challenge for many in the industry.

Top Benefits of Using Injection Molding Machine With Robot

This bar chart illustrates the key benefits of integrating robotic systems with injection molding machines, highlighting reductions in labor costs and improvements in safety across production lines.

Flexibility and Scalability for Diverse Manufacturing Needs Using Robotics

Injection molding machines paired with robotics offer remarkable flexibility and scalability. Manufacturers often face varying demands. Robotics can adapt to these changes quickly. Studies suggest that implementing robotics can increase manufacturing efficiency by up to 30%. This adaptation is crucial in a fast-evolving market.

The integration of robots into injection molding processes enables businesses to respond to production shifts seamlessly. Whether it’s changing product designs or adjusting volumes, robotic systems allow for rapid reconfiguration. Often, the initial investment in robotics pays off within a year, according to industry reports. Yet, many manufacturers still hesitate. Concerns about upfront costs and technical expertise linger.

Robotic systems can struggle in complex tasks. They need careful programming and maintenance. There’s a learning curve. Employees feel pressured to adapt. However, once in place, robots can handle precise operations that enhance quality. They can operate tirelessly and reduce human error. Embracing this technology requires open-mindedness and strategic planning from management.

Conclusion

The integration of an Injection Molding Machine With Robot offers numerous advantages in the manufacturing sector. Firstly, the automation of production processes significantly enhances efficiency, allowing for higher output rates while maintaining consistent quality. The collaboration between injection molding machines and robotic systems ensures enhanced precision in molding, resulting in fewer defects and superior product quality.

Moreover, this technology contributes to reduced labor costs, as it minimizes the need for manual intervention, subsequently improving safety protocols on the production floor. The flexibility and scalability afforded by robotic systems enable manufacturers to adapt quickly to varying production demands, while real-time data analysis facilitates ongoing optimization and maintenance, ensuring the machinery operates at peak performance. Overall, adopting an Injection Molding Machine With Robot is a strategic move toward a more efficient, cost-effective, and safe manufacturing environment.

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy