-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

How to Choose the Right Rubber Pump Impeller for Your Project?

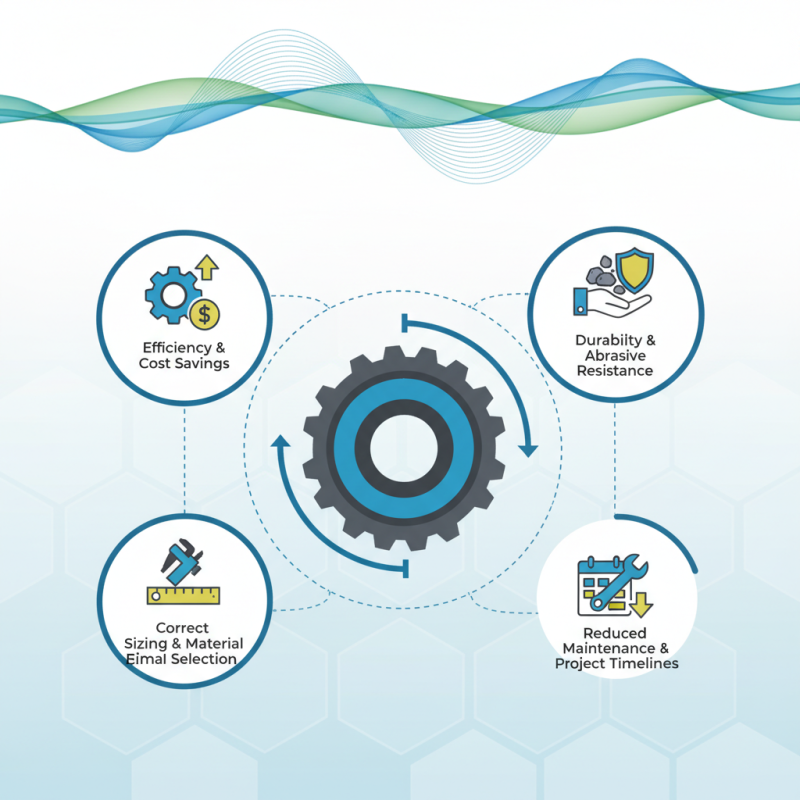

Choosing the right Rubber Pump Impeller is crucial for project success. A well-selected impeller ensures efficiency and reliability. According to a report by MarketsandMarkets, the global pump market is anticipated to reach $85.4 billion by 2027, emphasizing the importance of optimal components.

In various industrial applications, rubber impellers provide excellent durability and performance. They resist wear from abrasive materials and handle varying flow rates. Yet, many overlook the significance of correct sizing or material selection. An ill-fitted Rubber Pump Impeller can lead to inefficiencies and increased operational costs.

Manufacturers often focus on performance but neglect maintenance needs. A poorly chosen impeller can cause frequent replacements or repairs. This reflection can lead to project delays and budget overruns. Understanding all factors when selecting a Rubber Pump Impeller is essential for any successful project.

Understanding the Basics of Rubber Pump Impellers

Rubber pump impellers are crucial components in many pumping systems. They help create fluid movement efficiently. Understanding their basics can simplify your project. Rubber impellers are flexible. They can absorb shock and resist wear. This makes them ideal for handling various fluids, including slurries and corrosive materials.

When selecting an impeller, consider the fluid's viscosity. Thicker fluids require different designs than lighter ones. The impeller size and shape also matter. A well-sized impeller ensures optimal performance. Make sure to examine the installation requirements. Improper installation can lead to issues like vibration and reduced lifespan.

**Tips:** Always match the impeller material to the fluid type. This can prevent premature damage. Regularly inspect your impeller for signs of wear. A worn impeller can lead to decreased efficiency. It's essential to reflect on your choices. Consider if you’ve selected the best design for your application.

Factors to Consider When Selecting a Rubber Pump Impeller

Choosing the right rubber pump impeller requires careful consideration of several factors. The material of the impeller plays a critical role. Rubber with high abrasion resistance can extend the lifespan of your pump system. According to industry reports, using a quality rubber impeller can reduce downtime by up to 25%. This is an essential factor for operations aiming for efficiency.

Flow rate is another important consideration. It's vital to match the impeller design to the system's specific flow rate requirements. A mismatch can lead to inefficiencies or increased wear. When working in a high-pressure environment, consider the hardness of the rubber. Softer rubbers might deform under stress, affecting performance over time.

Temperature tolerance cannot be overlooked. Different rubber compounds withstand varying temperatures. Selecting the wrong type for extreme conditions can result in failures. Reports indicate that nearly 30% of pump malfunctions stem from improper material selection. Thus, a thorough evaluation of the operating conditions is paramount. Ignoring these details may lead to costly mistakes. Making an informed choice can significantly affect your project's success.

Types of Rubber Materials Used in Pump Impellers

When selecting a rubber pump impeller, the choice of materials is crucial. Various rubber types offer unique properties. Natural rubber is known for its excellent elasticity. It can handle dynamic loads well. However, it may not be the best for harsh chemicals.

Synthetic rubbers, like nitrile and EPDM, provide better resistance to oils and heat. Nitrile rubber is commonly used. It withstands oil exposure effectively. Conversely, EPDM is suitable for water applications. It has strong resistance to steam and aging. Each type has its strengths and weaknesses.

Choosing the right material requires careful consideration. Think about your specific application. Consider factors like temperature and chemical exposure. You might find that your first choice isn’t suitable. Testing different materials can lead to unexpected discoveries. Adjustments may be needed throughout the project. These reflections can help ensure a more effective pump performance.

How to Choose the Right Rubber Pump Impeller for Your Project? - Types of Rubber Materials Used in Pump Impellers

| Rubber Material | Properties | Applications | Temperature Range (°C) | Cost per kg (USD) |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | Oil-resistant, good abrasion resistance | Hydraulic pumps, automotive fuel systems | -30 to 100 | $2.00 |

| EPDM Rubber | Excellent weather resistance, good aging stability | Water pumps, HVAC systems | -50 to 150 | $1.80 |

| Natural Rubber (NR) | Excellent tensile strength, good elasticity | Agitation pumps, food processing | -30 to 80 | $1.50 |

| Silicone Rubber | Excellent temperature resistance, chemically inert | Pharmaceutical pumps, food grade applications | -60 to 230 | $3.50 |

| Neoprene Rubber | Good chemical stability, weather resistance | Pump seals, marine applications | -20 to 100 | $2.20 |

Evaluating the Performance Characteristics of Impellers

When selecting a rubber pump impeller, performance characteristics are critical. The efficiency of an impeller directly impacts the overall pumping system. According to industry reports, an efficient impeller can increase flow rates by up to 25%. This pushes the importance of evaluating variables like diameter, blade design, and material type.

Different projects demand specific performance traits. For instance, a larger diameter can enhance flow but may reduce pressure. Data suggests that impellers with more blades can improve reliability but may also lead to cavitation issues if not designed properly. In fluid dynamics, the balance between flow and pressure is delicate and often requires testing.

In practice, these factors present challenges. Choosing a high-performance impeller involves trade-offs. A detailed understanding of the operating conditions is essential to avoid pitfalls. For example, an impeller optimized for high flow might underperform in a system requiring high pressure. Each project has unique needs, urging thorough evaluation and testing to ensure the right match.

Maintenance Tips for Long-Lasting Rubber Pump Impellers

Maintaining rubber pump impellers is essential for their longevity. Regular inspection can prevent minor issues from becoming major problems. Check for signs of wear and tear. Look for cracks or deformation. These small details can significantly affect performance.

Keeping the impeller clean is equally important. Debris can accumulate over time. This buildup restricts flow and can lead to overheating. A quick rinse after use can make a difference. Don't overlook the pump's operating conditions. Excessive heat or harsh chemicals can wear down rubber.

Finally, consider the environment where the pump operates. High-pressure situations can lead to unexpected stress. Always monitor for irregular vibrations during operation. Act quickly if you notice changes. These proactive steps can extend the life of rubber pump impellers, ensuring reliable performance.

Rubber Pump Impeller Durability Analysis

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy