-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

Understanding the Importance of Level Control Valves in Modern Industrial Applications

In modern industrial applications, the significance of Level Control Valves cannot be overstated, as they play a crucial role in maintaining optimal fluid levels in various processes. According to industry reports, the global market for level control systems, including valves, is projected to reach approximately $7.5 billion by 2026, growing at a CAGR of around 5.4% from 2021 to 2026. These valves are essential for ensuring safety, efficiency, and reliability in operations, particularly in sectors such as chemical processing, wastewater treatment, and food and beverage production. By accurately regulating the flow of liquids and preventing overflow or depletion, Level Control Valves contribute to improved process control and reduced operational costs. As industries increasingly adopt automation and smart technologies, the demand for advanced level control solutions continues to rise, highlighting the indispensable role of these valves in modern manufacturing and production environments.

The Role of Level Control Valves in Optimizing Process Efficiency

Level control valves play a crucial role in optimizing process efficiency across various industrial applications. By maintaining desired fluid levels within tanks and vessels, these valves ensure that operations run smoothly and prevent overflows or shortages, which can lead to significant downtime or product loss. In sectors such as chemical processing, water treatment, and food production, precise level control translates into enhanced safety, improved product quality, and reduced waste.

The efficiency gained from effective level control is not just about maintaining balance; it also involves facilitating automated processes. Modern systems integrate these valves with sensors and process control systems, enabling real-time monitoring and adjustments. This dynamic interaction allows for optimized flow rates and helps manage energy consumption, further contributing to the overall sustainability of industrial operations. Therefore, the strategic implementation of level control valves is vital in achieving operational excellence and meeting production demands efficiently.

Key Factors Influencing the Selection of Level Control Valves

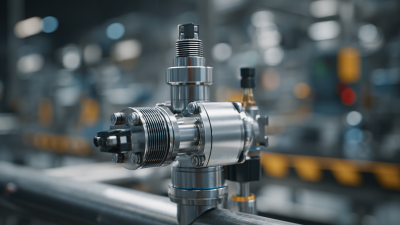

When selecting level control valves for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. One of the most critical factors is the type of fluid being controlled.

Different fluids, whether they are corrosive, viscous, or non-viscous, can significantly influence the material and design of the valve. For instance, corrosive fluids require valves made from resistant materials, while viscous fluids may necessitate valves with larger diameters to facilitate better flow.

Another important consideration is the operating environment in which the valve will function. Factors such as temperature, pressure, and potential exposure to harsh conditions can impact the valve's durability and reliability. Additionally, understanding the specific application needs, such as the required precision in level control and the response time, is vital for selecting the right valve. By taking these factors into account, engineers can choose level control valves that not only meet operational demands but also contribute to the overall efficiency and safety of the industrial process.

Common Applications of Level Control Valves in Various Industries

Level control valves play a crucial role in various industrial applications, ensuring the proper management of liquid levels in tanks, silos, and other containment systems. In the chemical industry, for instance, these valves are essential for maintaining the correct levels of reactants and products, preventing overflows or shortages that could disrupt processes or cause safety hazards. By providing precise control, these valves help in optimizing production efficiency and enhancing safety protocols.

Level control valves play a crucial role in various industrial applications, ensuring the proper management of liquid levels in tanks, silos, and other containment systems. In the chemical industry, for instance, these valves are essential for maintaining the correct levels of reactants and products, preventing overflows or shortages that could disrupt processes or cause safety hazards. By providing precise control, these valves help in optimizing production efficiency and enhancing safety protocols.

Similarly, in the water treatment sector, level control valves are employed to manage water levels in treatment basins and reservoirs. They help maintain consistent flow rates, which is vital for effective treatment processes. Additionally, in the food and beverage industry, level control valves are used to monitor and control the levels of ingredients and finished products, ensuring quality and compliance with industry standards. The versatility of level control valves across different sectors highlights their importance in managing liquid levels efficiently and safely.

Advances in Technology Impacting Level Control Valve Design and Function

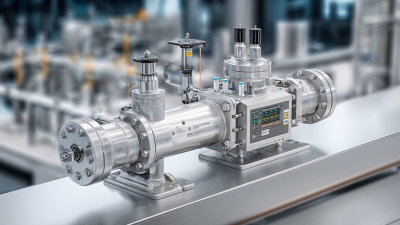

Recent advances in technology have significantly transformed the design and functionality of level control valves, making them indispensable in modern industrial applications. The integration of smart sensors and automation systems has enhanced the precision and responsiveness of these valves. For instance, the use of digital communication protocols allows for real-time monitoring and adjustments, enabling operators to maintain optimal fluid levels with minimal human intervention. This not only improves efficiency but also reduces the risk of overflow or dry run situations that can lead to costly downtimes.

Furthermore, innovations in materials and manufacturing techniques have led to the development of more durable and reliable level control valves. Today's valves are designed to withstand extreme environments, including high temperatures and corrosive substances, which is critical in industries such as chemical processing and oil and gas. Additionally, modular designs facilitate easier maintenance and quicker replacements, ensuring that production processes remain uninterrupted.

As the demand for higher efficiency and lower operational costs continues to grow, these technological advancements in level control valves play a crucial role in meeting the challenges of modern industrial operations.

Challenges and Solutions in Implementing Level Control Valves in Systems

Level control valves play a crucial role in modern industrial applications by regulating fluid levels effectively. However, implementing these systems is not without its challenges. One common issue is the selection of the appropriate valve type. Industries often face difficulties in choosing between different technologies, such as pneumatically or electrically actuated valves, which can lead to inefficiencies if not matched properly with the system requirements. Proper training and understanding of the application can significantly alleviate these initial hurdles.

Level control valves play a crucial role in modern industrial applications by regulating fluid levels effectively. However, implementing these systems is not without its challenges. One common issue is the selection of the appropriate valve type. Industries often face difficulties in choosing between different technologies, such as pneumatically or electrically actuated valves, which can lead to inefficiencies if not matched properly with the system requirements. Proper training and understanding of the application can significantly alleviate these initial hurdles.

Tips: When choosing a level control valve, always assess the specific fluid properties and the environmental conditions. This can prevent issues like corrosion or pressure fluctuations that could undermine valve performance.

Another challenge is the integration of level control valves into existing systems. Aging infrastructure may not accommodate newer technologies without significant modifications. To address this, careful planning and phased implementation are recommended. Conducting a thorough assessment of the current system layout can help identify any necessary upgrades and ensure compatibility with the new installations.

Tips: Regularly review the existing infrastructure and plan for gradual integration to minimize downtime. This proactive approach can save time and resources while enhancing system efficiency.

Related Posts

-

The Future of Smart Automation in Best Automatic Valves

-

Unlocking Global Opportunities for Pressure Release Valves at the 2025 Canton Fair

-

Ultimate Pressure Control Valve Maintenance Checklist for Optimal Performance

-

Exploring the Unique Features and Applications of the Best Air Valves in Your Industry

-

Navigating Import and Export Certification for the Best Water Pressure Reducing Valve

-

How to Select the Perfect Automatic Valve for Your Industrial Needs

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy