-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

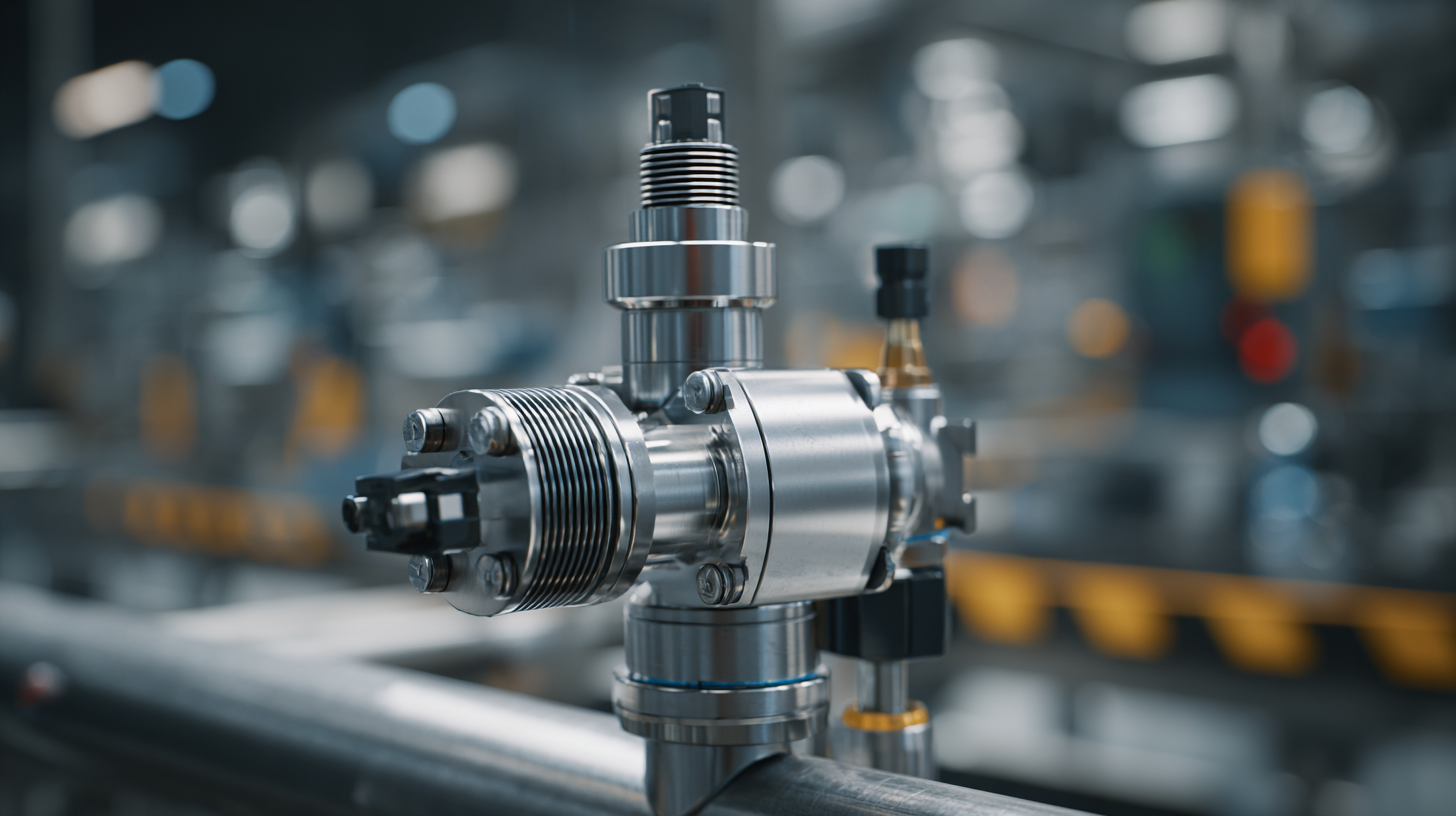

How to Select the Perfect Automatic Valve for Your Industrial Needs

In the ever-evolving landscape of industrial operations, the selection of the right automatic valve is crucial for optimizing performance and ensuring efficiency across processes. According to a recent report by MarketsandMarkets, the global automatic valve market is projected to reach USD 4.55 billion by 2025, reflecting a CAGR of 6.1% from 2020. This significant growth underscores the increasing demand for advanced automatic valves that enhance system automation, improve safety, and reduce operational costs. Selecting the perfect automatic valve involves understanding the specific requirements of your application, considering factors such as flow characteristics, pressure ratings, and material compatibility. As industries pursue greater efficiency and sustainability, making informed choices in automatic valve selection not only contributes to process optimization but also aligns with broader trends in smart manufacturing and automation technology.

Understanding the Different Types of Automatic Valves for Industrial Applications

When selecting the perfect automatic valve for industrial applications, understanding the different types available is crucial. Automatic valves can be categorized into various types, including solenoid valves, pneumatic valves, and electric valves, each designed to handle specific fluid control requirements. According to a report by MarketsandMarkets, the global automatic valve market was valued at approximately $15 billion in 2022 and is projected to reach over $22 billion by 2028, growing at a CAGR of around 7.5%. This growth indicates a rising demand for efficient fluid control solutions in industries like oil and gas, water and wastewater management, and food processing.

In addition, solenoid valves are particularly suitable for applications that require rapid response times and precise control, often used in irrigation systems and cooling systems. Meanwhile, pneumatic valves are preferred in environments where high-speed actuation is necessary, and they are widely employed in automation systems across various sectors. Electric valves, on the other hand, provide reliable operation in applications that require low to moderate flow rates. This diverse range of automatic valves enables industries to optimize processes, reduce operational costs, and improve safety standards, all of which are essential for maintaining competitiveness in today’s market.

Evaluating Key Factors for Automatic Valve Selection: Size, Pressure, and Flow Rate

When selecting the perfect automatic valve for industrial applications, it's crucial to evaluate key factors such as size, pressure, and flow rate. The size of the valve is typically determined by the pipe diameter and the specific requirements of the system. Proper sizing ensures that the valve can effectively control the flow without creating excessive pressure drops or flow restrictions. Manufacturers provide guidelines and selection charts to assist in determining the appropriate valve size, which can significantly influence the overall performance of the system.

Pressure ratings are another vital consideration. Each valve is designed to withstand specific pressure ranges, and selecting a valve that can handle the maximum operating pressure of your system is essential for safety and durability. It's important to account for not only the normal operating pressure but also the potential for pressure spikes during system operation. Additionally, understanding the flow rate is critical; it determines the valve's ability to maintain the desired fluid dynamics within the system. Evaluating these factors thoroughly will ensure the chosen automatic valve operates efficiently and meets the specific demands of your industrial needs.

Exploring Control Technologies: Electric, Pneumatic, and Hydraulic Valves

When selecting an automatic valve for industrial applications, it's crucial to consider the various control technologies available. Electric valves are known for their precision and ease of integration with digital control systems. They are ideal for applications requiring exact flow control and can be easily operated via remote commands. Additionally, electric valves offer high reliability with minimal maintenance, making them an excellent choice for facilities seeking efficiency and longevity.

On the other hand, pneumatic valves utilize compressed air to operate, providing rapid response times that are essential in high-speed operations. These valves are often favored in environments where explosive gases or other hazardous materials are present, as they are less prone to ignition compared to electrical systems. Hydraulic valves, meanwhile, excel in applications that require heavy lifting or high-pressure operations. With their robust construction and ability to handle significant loads, hydraulic valves are commonly found in manufacturing processes and machinery where power is paramount.

Each of these control technologies has unique advantages that make them suitable for different industrial needs, so understanding their characteristics is key to making an informed decision.

Assessing Material Compatibility for Valve Durability and Performance

When selecting an automatic valve for industrial applications, ensuring material compatibility is crucial for optimizing durability and performance. According to a 2021 report by Grand View Research, the global industrial valve market is projected to reach USD 93.02 billion by 2025, with increasing emphasis on advanced materials being a key driver. Selecting the right materials not only extends the lifespan of the valve but also enhances resistance to corrosive substances and extreme temperatures found in various industrial environments.

Material compatibility is particularly vital in industries such as oil and gas, where valves often face aggressive media. A study published in the Journal of Industrial Engineering found that valves made from high-performance alloys can withstand corrosive agents significantly better than traditional materials. For instance, valves constructed from stainless steel exhibit improved stress corrosion cracking resistance, making them suitable for sour service applications. Therefore, conducting a thorough assessment of the operating environment and understanding material properties can significantly impact a valve's operational reliability and maintenance costs over time. Choosing the right materials ensures that operational downtime is minimized, maintaining efficiency and safety across industrial processes.

How to Select the Perfect Automatic Valve for Your Industrial Needs - Assessing Material Compatibility for Valve Durability and Performance

| Valve Type | Material Compatibility | Temperature Range (°C) | Pressure Rating (Bar) | Common Applications |

|---|---|---|---|---|

| Ball Valve | PVC, CPVC, Stainless Steel | -20 to 120 | 10 to 20 | Water Treatment, Chemical Processing |

| Gate Valve | Cast Iron, Stainless Steel | -50 to 200 | 6 to 30 | Oil & Gas, Water Supply |

| Globe Valve | Brass, Stainless Steel | -10 to 150 | 10 to 25 | Heating Systems, Fuel Lines |

| Check Valve | Stainless Steel, PVC | -30 to 120 | 5 to 15 | Pumping Systems, Wastewater |

Ensuring Compliance: Industry Standards and Certifications for Automatic Valves

When selecting an automatic valve for industrial applications, ensuring compliance with industry standards and certifications is crucial. Various organizations, such as the American National Standards Institute (ANSI) and International Organization for Standardization (ISO), set rigorous requirements for valves, impacting safety, performance, and reliability. For instance, the ISO 9001 certification ensures that manufacturers adhere to stringent quality management practices, thereby guaranteeing that the valves produced meet both operational and performance standards. According to a report by the Valve Manufacturers Association (VMA), approximately 60% of valve-related failures in industrial settings are attributed to non-compliance with these standards.

Moreover, different industries may necessitate compliance with certain regulations specific to their operations. For example, valves used in the oil and gas sector must comply with the American Petroleum Institute (API) standards, which include API 598 for valve inspection and testing. These standards not only mitigate risks of malfunctions and accidents but also enhance operational efficiency. A study by Research and Markets indicates that the automatic valve market is expected to grow at a compound annual growth rate (CAGR) of 6% between 2021 and 2026, highlighting the increased focus on quality control and adherence to industry certifications. By prioritizing compliance, industries can ensure they select the optimal automatic valves tailored to their specific needs while safeguarding overall operational integrity.

Related Posts

-

The Future of Automatic Valves Trends Innovations and Market Growth Insights

-

Top Control Valve Manufacturers from China at the 137th Canton Fair

-

Common Challenges Faced When Selecting the Best Pressure Relief Valve Solutions

-

Navigating Import and Export Certification for the Best Water Pressure Reducing Valve

-

Exploring the Unique Features and Applications of the Best Air Valves in Your Industry

-

7 Amazing Features of the Best Industrial Valves You Should Know

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy