-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

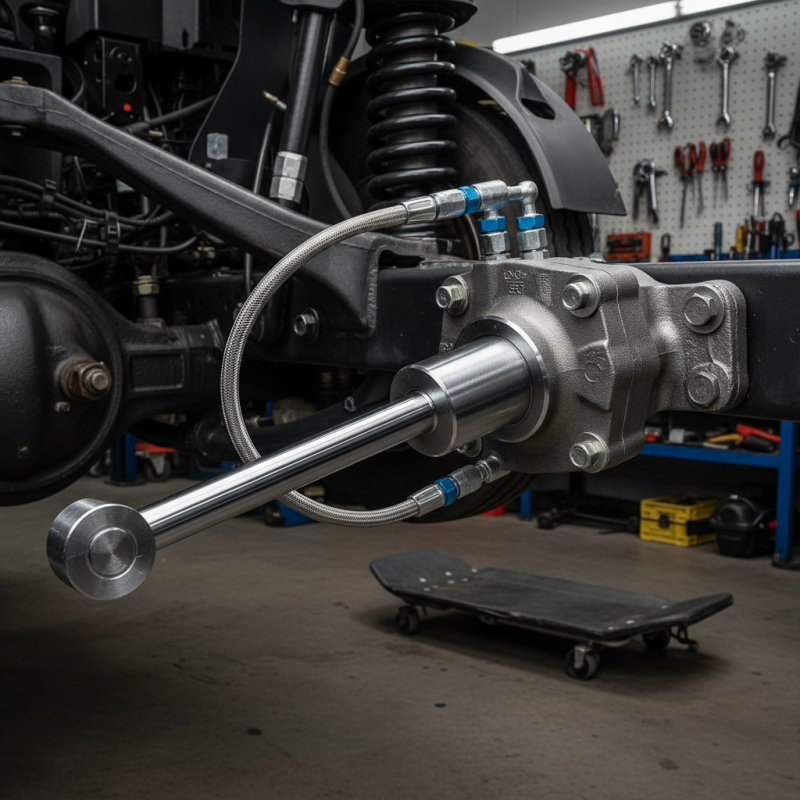

What is Steering Cylinder and How Does It Work?

A Steering Cylinder is a crucial component in hydraulic steering systems, playing a pivotal role in vehicle maneuverability. According to recent industry reports, around 60% of commercial vehicles now utilize hydraulic steering for enhanced performance and responsiveness. This indicates a significant reliance on steering cylinders in modern automotive design. The functionality of the steering cylinder involves converting hydraulic pressure into mechanical force, ultimately guiding the vehicle’s direction.

Many engineers note that proper maintenance of the steering cylinder is vital. Neglect can lead to reduced efficiency and responsiveness. In fact, studies show that over 30% of steering issues in vehicles stem from faulty cylinders. Regular checks can prevent these problems and improve safety. Yet, many drivers overlook this essential maintenance step.

Understanding the steering cylinder's operation can demystify its importance. This knowledge fosters better vehicle care. Drivers tend to focus on engine performance, often forgetting the steering systems. This negligence can lead to serious consequences on the road. As vehicles evolve, so too must our understanding of these components. It’s essential to engage in proactive discussion about these systems for optimal safety and performance.

Definition of Steering Cylinder and its Role in Vehicle Dynamics

A steering cylinder is a vital component in a vehicle's steering system. It plays a significant role in vehicle dynamics by converting the rotational motion of the steering wheel into linear motion. This mechanism allows the vehicle to turn precisely at various speeds. The steering cylinder operates under hydraulic or electric power, offering smooth control.

Many drivers overlook the importance of regular maintenance. Keeping the steering system lubricated can prevent unexpected failures. Check for leaks often. A small leak can lead to a larger problem. Ensure connections are secure. This simple practice can prolong your cylinder’s lifespan.

Understanding the steering cylinder is essential for safe driving. It influences handling and stability. A malfunction can make steering unpredictable. Always listen for odd noises while turning. An unusual sound might be a sign. Pay attention to how your vehicle responds. If it feels off, it’s best to investigate. A careful driver knows when to seek help.

Components of a Steering Cylinder and Their Functions

A steering cylinder is an essential part of hydraulic steering systems in vehicles. It plays a crucial role in controlling the direction of movement. Understanding the components of a steering cylinder helps in grasping its functionality.

The main components include the cylinder body, piston, and seals. The cylinder body houses the piston and contains hydraulic fluid. As fluid enters the cylinder, it pushes the piston, which moves the steering rack. This movement translates to the wheels, enabling precise directional control. Seals ensure that the hydraulic fluid remains contained, preventing leaks during operation.

Tips: Regular maintenance is vital. Inspect seals for wear and tear. Minor leaks can lead to significant issues over time.

Another key component is the hydraulic fluid itself. It transmits force and facilitates smooth movement. Using the right fluid type is crucial for optimal performance. Studies show that poor fluid quality can decrease responsiveness by 30%.

In conclusion, understanding each part's role can lead to better vehicle handling. Regular checks and proper fluid management are essential for safety and performance. Stay aware of how these components work together for a safe driving experience.

How Steering Cylinders Operate: Mechanisms Explained

Steering cylinders play a crucial role in steering systems. They convert hydraulic pressure into mechanical motion. This allows vehicles to change direction smoothly and efficiently. When the driver turns the steering wheel, hydraulic fluid flows into the cylinder. This action creates pressure, moving the piston inside the cylinder.

Inside the steering cylinder, the piston is connected to the steering linkage. As fluid enters, the piston moves to one side. This movement pushes the linkage, turning the wheels. It’s a simple mechanism, yet essential for vehicle control. However, issues can arise. If the hydraulic fluid leaks, steering becomes difficult. A worn piston can also cause inefficiency. Regular maintenance is vital to ensure proper function.

In conclusion, understanding how steering cylinders work is important for vehicle safety. Their operation is straightforward but not always perfect. Drivers should be aware of potential problems. Regular checks can help identify leaks or wear. This proactive approach leads to safer driving experiences.

What is Steering Cylinder and How Does It Work? - How Steering Cylinders Operate: Mechanisms Explained

| Component | Function | Mechanism | Material | Common Applications |

|---|---|---|---|---|

| Steering Cylinder | Converts hydraulic pressure into linear motion | Contains a piston that moves in response to fluid pressure | Aluminum or Steel | Automobiles, trucks, and construction equipment |

| Hydraulic Fluid | Transmits force within the steering system | Must be incompressible to enable efficient movement | Engineered fluid | Automotive steering systems |

| Piston | Drives the steering mechanism | Moves linearly when hydraulic pressure is applied | Steel or Aluminum | Heavy machinery, vehicles |

| Seals | Prevents leakage of hydraulic fluid | Ensures a tight fit between moving and stationary parts | Rubber or synthetic materials | Hydraulic systems in vehicles |

| Mounting Bracket | Holds the steering cylinder in place | Supports the entire assembly during operation | Steel | Various industrial applications |

Common Types of Steering Cylinders Used in Vehicles

Steering cylinders play a vital role in vehicle maneuverability. They are components of hydraulic steering systems that facilitate smooth turning. Different types of steering cylinders are used in vehicles today, each serving specific needs. The two most common types are double-acting cylinders and single-acting cylinders.

Double-acting steering cylinders are widely used in commercial vehicles. These cylinders provide power in both extending and retracting motions, which helps in precise steering control. They often require a hydraulic pump for operation. Single-acting cylinders, on the other hand, use hydraulic pressure in one direction only. They are simpler and often found in lighter vehicles, but they might lack the responsiveness of double-acting models.

Installation and maintenance of these cylinders can be tricky. A poorly fitted cylinder can lead to steering issues. Regular checks are necessary to ensure optimal functionality. Many vehicle owners overlook this aspect. It can cause unnecessary wear on the steering system. Issues like fluid leaks or cylinder damage should not be ignored. Proper attention can ensure better vehicle performance.

Maintenance Tips for Steering Cylinders to Ensure Optimal Performance

Steering cylinders play a crucial role in vehicle control. Regular maintenance is essential to ensure optimal performance. A study by the Society of Automotive Engineers highlights that nearly 30% of steering system failures could be attributed to lack of maintenance. This statistic is alarming and shows the importance of vigilance.

Inspect your steering cylinder regularly. Look for leaks or cracks that may compromise its integrity. Use proper tools to check fluid levels and cleanliness. It’s recommended to replace fluid every 30,000 miles. This proactive approach helps maintain a responsive steering system. Additionally, ensure all connections are tight. Loose connections can lead to inefficiency and potential fluid loss.

Staying alert is key. Be attentive to any changes in handling. Unusual noises or stiff steering could indicate problems. Address these issues promptly to avoid costly repairs. Remember, a well-maintained steering cylinder contributes to safety. Neglecting it could lead to serious consequences on the road.

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy