-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

Top 10 Auto Parts Bearings You Need to Know About?

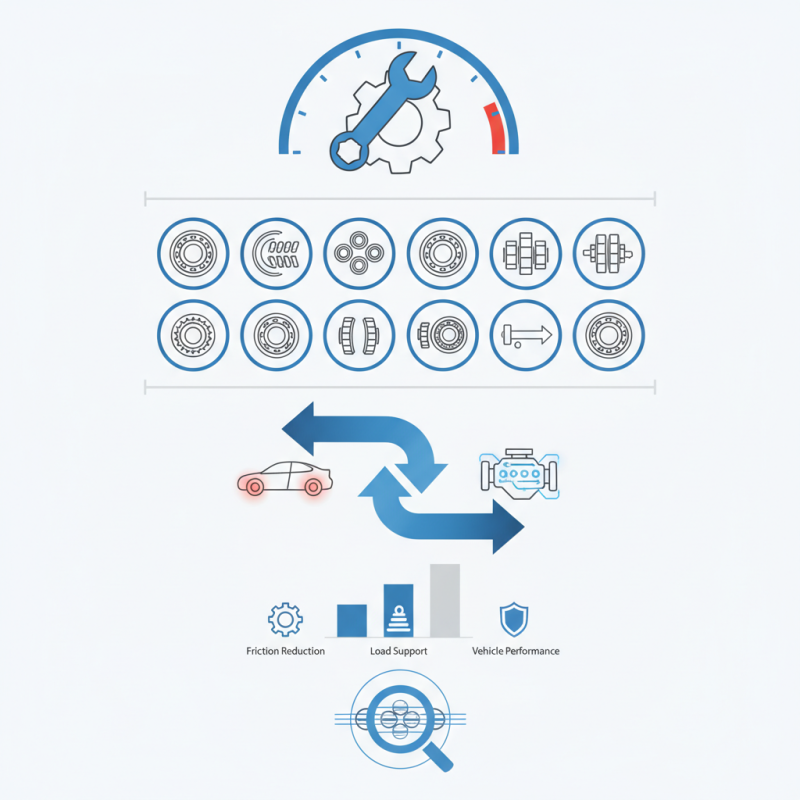

In the ever-evolving world of auto parts, bearings play a critical role. Renowned expert, Dr. John Miller, once stated, “Quality in Auto Parts Bearings is non-negotiable for vehicle performance.” Understanding this, enthusiasts and mechanics alike must explore the top auto parts bearings available today.

Auto parts bearings are essential for smooth operation in vehicles. They reduce friction and support loads for various components. Yet, many underestimate their importance. A poor-quality bearing can lead to significant issues in performance and safety.

As we delve into the top 10 auto parts bearings, it’s vital to recognize that not all products are created equal. Quality varies greatly among manufacturers. Some offer durability, while others may not meet expectations. This guide aims to shed light on those bearings you truly need to know about.

Top 10 Auto Parts Bearings: An Overview of Key Components

When it comes to auto parts, bearings play a crucial role. They reduce friction, allowing moving parts to operate smoothly. From wheel hubs to engine components, these seemingly small elements are vital. Without them, vehicles would struggle to function efficiently. It is interesting to note that not all bearings are created equal, and performance can vary widely.

Different types of bearings serve unique purposes. For instance, roller bearings withstand heavy loads while ball bearings excel in agility. Some are designed for high-speed applications, while others focus on durability. Understanding these functions is essential for both mechanics and DIY enthusiasts. Yet, many overlook the significance of selecting the right bearing for their vehicle. This might lead to premature wear and potential failure.

Regular maintenance is just as important. Cleaning and lubrication can extend the lifespan of bearings. In the rush of daily routines, people often forget this. Proper care can prevent costly repairs down the line. It becomes evident that being informed about bearings can save time and money.

Understanding the Different Types of Auto Bearings in the Market

Auto bearings play a crucial role in vehicle performance. They reduce friction and support moving parts. Understanding different types of bearings is essential for any car owner.

There are several key types of auto bearings: roller bearings, ball bearings, and journal bearings.

Roller bearings use cylindrical rollers to handle heavy loads. They are common in truck axles. Ball bearings feature metal balls, offering smooth movement. They are ideal for lighter applications, like fan motors. Journal bearings, on the other hand, support rotating shafts. They are usually found in engines and transmissions.

Tips: When choosing bearings, consider the load and speed requirements. Always check the compatibility with your vehicle. Routine maintenance can prolong the lifespan of bearings. Inspect them for wear and replace if necessary.

Many car owners overlook the importance of auto bearings. They often focus on more visible components. However, bearing issues can lead to significant problems. Poor performance or noise from the wheels may indicate bearing failure. Regular checks can save time and money down the road.

Key Factors Influencing Bearing Performance and Longevity

When it comes to auto parts, bearings play a crucial role in performance. Several key factors influence their longevity. Quality materials affect durability. Look for strong metals that can withstand high temperatures and pressure. A well-designed bearing also enhances efficiency.

One important aspect is lubrication. Proper lubrication reduces friction and wear. This helps to maintain consistent performance over time. Regular checks can prevent premature failure. Without sufficient lubrication, bearings can fail quickly.

Tip: Always match bearings to their specific applications. Each vehicle has different requirements. An ill-fitting bearing may result in early degradation. Pay attention to installation as well; improper installation can lead to alignment issues. Remember, even with quality parts, neglect can lead to short lifespans. Sometimes, the best parts fail due to a lack of care.

Top 10 Auto Parts Bearings Performance Comparison

This chart displays the performance ratings of the top 10 auto parts bearings based on various factors that influence their longevity and effectiveness. Each bearing is rated on a scale from 1 to 10, with higher ratings indicating better performance.

Industry Standards and Specifications for Auto Parts Bearings

When it comes to auto parts bearings, adhering to industry standards is crucial. Quality and performance often hinge on compliance with specific regulations. These standards ensure that bearings can withstand the rigors of daily use. A few important specifications include load ratings, material composition, and dimensional accuracy. Understanding these can be daunting, especially for those new to the industry.

Dimensions and tolerances matter significantly. A bearing that doesn't meet specified tolerances may lead to premature failure. For example, too much play or insufficient fit can cause vibrations. Such issues ultimately affect vehicle performance. Moreover, materials play a critical role in durability. Common options range from chrome steel to ceramic, each with its own pros and cons. It's essential to choose wisely. While many options seem suitable, not all will perform reliably under specific conditions.

Reflecting on industry advancements, the evolution of bearing technology is noteworthy. New innovations continually arise, yet not all are universally adopted. Some designs may appear superior but lack real-world validation. It's vital to examine user feedback and empirical data before selecting a bearing. A deeper dive into these factors can unveil both opportunities and pitfalls in the quest for the best auto parts bearings.

Emerging Trends in Auto Bearings Technology and Innovation

The automotive bearing industry is witnessing notable changes driven by technological advancements. Emerging trends focus on lightweight materials, which can improve fuel efficiency. Reports indicate that adopting advanced composites can reduce weight by up to 30%. This shift is essential as manufacturers seek to meet stricter emissions regulations.

Another key trend is the integration of smart technology into bearings. Sensors embedded in bearings can monitor performance in real time. This innovation allows for predictive maintenance, reducing downtime and costs. According to recent industry studies, predictive maintenance can cut maintenance costs by 25% to 30%. However, the adoption of these technologies comes with challenges. Training staff to handle complex systems is essential, yet many companies struggle with this transition.

Furthermore, sustainability is becoming a priority. Many manufacturers are now focusing on eco-friendly production processes. Using recycled materials in bearings is one approach. A report suggests that increasing recycling in this sector could decrease the carbon footprint significantly. Despite these promising developments, the industry must address scalability. Transitioning to new technologies poses logistical hurdles, often making the implementation process slower than anticipated.

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy