-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

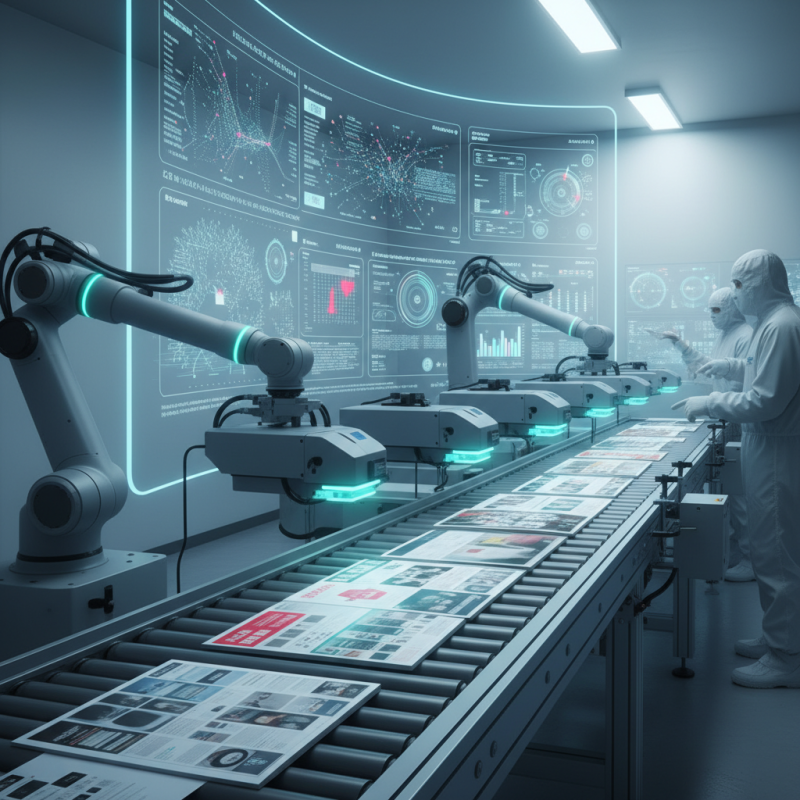

2026 Top Print Flaw Detection System Innovations Explained?

The Print Flaw Detection System is vital in the printing industry. As reported by MarketsandMarkets, the print quality assurance market is projected to reach $5.9 billion by 2025. With increasing demand for high-quality printed materials, innovative detection systems are essential.

In 2026, cutting-edge technologies in Print Flaw Detection Systems aim to reduce errors and enhance efficiency. These innovations include advanced machine learning algorithms and high-resolution imaging techniques. Companies are investing significantly in these systems to avoid costly reprints and ensure customer satisfaction.

However, not all systems are perfect. Some may struggle to detect subtle flaws, leading to potential quality issues. Regular advancements are necessary, and companies must continuously assess their detection capabilities. Embracing new technologies can mitigate risks, but a critical eye is needed to avoid overlooking imperfections. The landscape of print flaw detection is evolving, and staying ahead is crucial for success.

Current Challenges in Print Flaw Detection Technologies

Print flaw detection technologies face significant challenges today. The evolving complexity of print materials often leads to defects that are hard to identify. According to a 2023 industry report, around 30% of printed products experience flaws that go unnoticed during production. This can result in substantial financial losses and damage to brand reputation.

One major challenge is the integration of advanced software with existing hardware. Many facilities still rely on outdated systems. Upgrading technology can be costly and disruptive. Additionally, human oversight remains a critical factor. Even with automated systems, around 40% of errors were attributed to operator negligence in a recent study. This highlights the ongoing need for better training and support in the workforce.

Another issue is the variability in print materials. Different substrates and inks behave uniquely, complicating defect detection. A survey indicated that 65% of print professionals struggle to adapt their processes to varying materials. Inconsistent quality assurance methods further exacerbate this issue. Addressing these challenges is crucial for improving print quality and reducing waste.

Key Innovations in Print Flaw Detection Systems for 2026

In 2026, innovations in print flaw detection systems are set to transform the industry. Enhanced imaging technology can now identify defects with incredible precision. These systems leverage advanced algorithms that analyze each print in real-time. The capability to distinguish between minor imperfections and major flaws leads to improved quality assurance.

Tip: Regular training on the latest technologies ensures staff are up-to-date. Knowledge is key to leveraging new systems effectively.

Another notable innovation is the use of AI and machine learning. These technologies learn from historical data and adapt to new printing processes. As the systems evolve, they become better at predicting potential issues. However, reliance on AI can be a double-edged sword. Organizations must remain vigilant and continually monitor outputs.

Tip: Conduct periodic reviews of system performance. This practice helps to catch underlying issues before they escalate.

Finally, connectivity plays a crucial role. Integrating print flaw detection with other manufacturing systems promotes seamless communication. Yet, complexities may arise during integration. Teams should be prepared for unforeseen challenges. Reflecting on past experiences can guide future implementations.

Comparative Analysis of Leading Print Flaw Detection Solutions

In the printing industry, detecting flaws has become crucial. Recent innovations in print flaw detection systems are driving this change. A comparative analysis of these systems reveals significant differences in efficiency and accuracy. Some systems utilize advanced algorithms that adapt to varied printing conditions. Others rely on sensor technology, detecting imperfections in real time.

Tips for selecting a print flaw detection solution: focus on ease of integration. Systems should combine seamlessly with existing workflows. Consider user-friendliness as well; complex interfaces can cause confusion. Look at customer feedback. Systems with high satisfaction rates often reflect better reliability.

Many innovations still struggle with specific issues. For instance, some algorithms may misinterpret natural variations in print designs, leading to false positives. This can result in unnecessary downtime. Moreover, instances of missed flaws highlight the need for ongoing adjustments. Each system has its strengths and weaknesses, making thorough testing essential.

Future Trends in Print Flaw Detection Technology Development

The future of print flaw detection technology is evolving rapidly. Innovations are focusing on enhanced accuracy and speed. Advanced algorithms are being developed to identify defects. These algorithms analyze data in real-time, which reduces waste and improves efficiency. High-resolution cameras and sensors are becoming standard. They capture minute details that human eyes might miss.

However, integrating these technologies poses challenges. Not all systems can adapt to various printing environments. Some tools may struggle with diverse materials. Additionally, the cost of implementing new systems can be significant. Companies often need to weigh the benefits against these expenses. Continuous training for operators is also essential. A skilled workforce can make a substantial difference in leveraging technology.

As these trends unfold, companies must remain adaptable. The market demands flexibility and responsiveness. Future systems may incorporate machine learning. This could allow them to learn from past flaws. Users will need to remain vigilant about these advancements. Keeping pace with technology can be difficult. Still, it is crucial for staying competitive in the printing industry.

Impact of AI and Machine Learning on Print Quality Assurance

The impact of AI and machine learning on print quality assurance is revolutionary. According to a recent industry report, integrating AI can improve defect detection rates by up to 90%. Traditional methods often miss subtle flaws, resulting in wasted materials and decreased profits. Automated systems powered by machine learning analyze vast amounts of data quickly. This capability allows for real-time adjustments, leading to higher precision outputs.

However, challenges persist. Not all AI systems can be seamlessly integrated into existing workflows. The learning curve for workers can be steep. In a survey, 40% of companies reported difficulty in training staff on new technologies. Additionally, reliance on AI raises concerns about data privacy. Sometimes the technology falls short, leading to unresolved issues. For example, complex print jobs may still require human oversight to catch errors that AI might overlook.

Despite these challenges, the benefits of improved quality assurance are clear. Print manufacturers can reduce defects, saving both time and money. Machine learning algorithms continuously learn and adapt, enhancing future print runs. While the journey is not free of obstacles, the potential for higher quality standards is a significant motivator for innovation in the industry.

Impact of AI and Machine Learning on Print Quality Assurance

This chart illustrates the effectiveness of various print flaw detection systems in terms of defect reduction percentage over the past few years, highlighting the influence of AI and machine learning innovations in the industry.

Article Source:

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy