-

Solutions

-

Waterworks

Pressure Reducing

Pressure Sustaining / Pressure Relief

Flow Control valves

Float Valves - Level Control

Electrically Actuated Valves

Pressure Modulation - Remote Control

Altitude Valves - Level Control

Burst Control Valves

Pump Control

CLA-VAL "HYTROL" Main Valve

Valve Controllers and Data Loggers

Air Valves

See allWaterworks

-

Military Fuelling

-

- About us

-

Blog

- Support

-

Contact

Blog

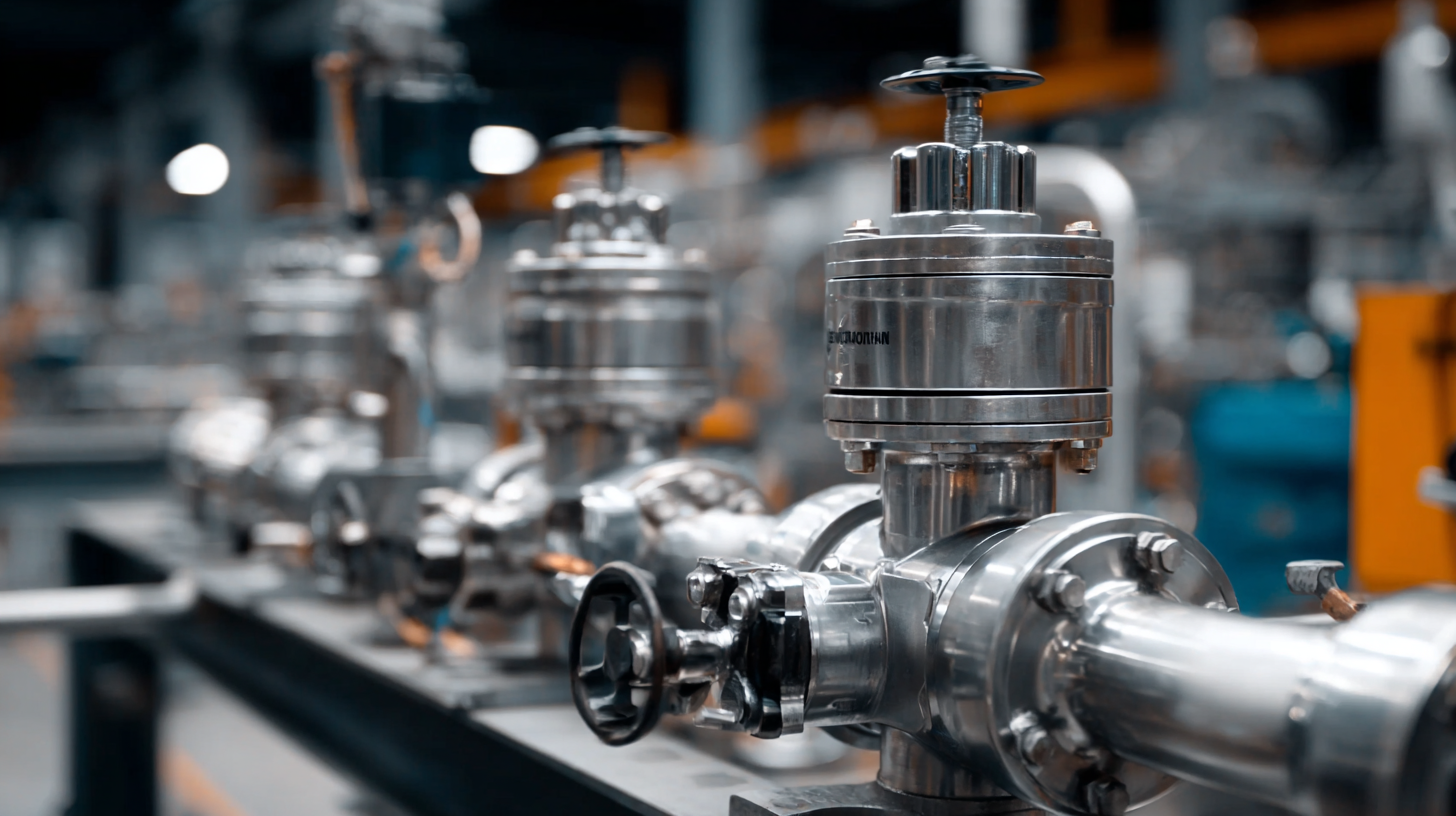

Exploring the Unique Features and Applications of the Best Air Valves in Your Industry

In today's rapidly evolving industrial landscape, the significance of high-quality air valves cannot be overstated. According to a recent report by MarketsandMarkets, the global air valve market is projected to reach USD 3.2 billion by 2025, reflecting a compound annual growth rate of 4.8% over the next few years. This surge is largely driven by the increasing demand for efficient air management systems across various sectors, including manufacturing, HVAC, and automotive industries. As industries strive for greater efficiency and sustainability, the role of air valves has become pivotal, facilitating not only the control of airflow but also enhancing energy conservation and operational safety. This blog aims to delve into the unique features and applications of the best air valves currently available, highlighting exceptional products from leading Chinese manufacturers that are setting new benchmarks in the global marketplace.

Key Characteristics of Top Air Valves for Industrial Efficiency

The efficiency of industrial processes heavily relies on the performance of air valves, which play a crucial role in regulating air distribution and maintaining system integrity. Top air valves are characterized by their durability, precision control, and adaptability to various operational demands. According to recent industry analyses, the air compressor market is set to grow significantly, predicted to reach substantial market size by 2030, driven by advancements in technology and increasing demand across sectors.

Tips for selecting the best air valves include evaluating their compatibility with your specific systems, ensuring they meet engineering standards, and determining the operational environment they will be used in. Furthermore, high-quality valves can minimize maintenance costs and increase system efficiency.

In HVAC applications, particularly concerning air quality and energy consumption, selecting air valves that optimize airflow can enhance indoor environments significantly. It’s essential to keep abreast of the latest industry trends, including the advancing technologies in air management systems, which are focused on sustainability and reducing energy usage. By investing in top-performing air valves, industries can achieve better operational performance and a healthier working atmosphere.

Comparative Analysis of Air Valve Types for Specific Applications

Air valves play a crucial role in a variety of industries, from water treatment and HVAC systems to manufacturing and automation.

A comparative analysis of different air valve types reveals significant variations in performance, efficiency, and suitability for specific applications.

Air valves play a crucial role in a variety of industries, from water treatment and HVAC systems to manufacturing and automation.

A comparative analysis of different air valve types reveals significant variations in performance, efficiency, and suitability for specific applications.

For instance, according to a report by the International Journal of Fluid Mechanics,

butterfly valves are recognized for their compact size and light weight, making them ideal for low-pressure applications where space and energy efficiency are paramount.

In contrast, globe valves are better suited for applications requiring precise flow control and tight shut-off,

often preferred in chemical processing environments.

The choice of air valve can greatly affect system performance.

The Flow Control Journal reports that the integration of solenoid-operated air valves can enhance response times by up to 30%,

which is vital in automated systems. Additionally, pilot-operated valves offer significant advantages in high-pressure scenarios,

providing reliability and increased durability according to the American Society of Mechanical Engineers (ASME).

This diversity in air valve technology highlights the necessity for industry professionals

to carefully assess their specific application needs to select the most effective solution,

ultimately optimizing operational efficiency and safety across various processes.

Innovative Technologies Enhancing Air Valve Performance

The air valve industry has seen remarkable advancements thanks to innovative technologies that enhance performance and reliability. One of the standout features in current air valves is the integration of smart technologies, such as IoT sensors, which enable real-time monitoring and data analysis. This not only allows for efficient operation but also helps in predictive maintenance, minimizing downtime and reducing costs.

When selecting air valves for your operations, consider opting for those equipped with these smart features. Additionally, look for models that offer adjustable flow rates and pressure settings to ensure optimal performance tailored to your specific application. Regular maintenance is crucial—perform routine inspections and cleanings to keep the valves operating efficiently, and always stay updated on the latest technologies available in the market.

Another innovative aspect is the use of advanced materials that enhance durability and corrosion resistance. This improves the longevity of air valves, particularly in harsh environments. Ensure your chosen valves utilize these materials to prolong their lifespan and maintain operational integrity. By focusing on these technological advancements, your industry can significantly improve both performance and efficiency.

Best Practices for Maintaining and Troubleshooting Air Valves

Maintaining and troubleshooting air valves is essential for ensuring optimal performance in various industries. According to a report by the Fluid Power Institute, improper maintenance can lead to efficiency losses of up to 20% in pneumatic systems. Regular inspections and adherence to maintenance schedules can significantly reduce these inefficiencies. Ensuring that air valves are free from debris and properly lubricated can also enhance their longevity.

Tip: Schedule routine maintenance checks every three months to inspect for leaks or wear in seals and diaphragms. Utilizing predictive maintenance tools can help identify potential issues before they escalate into costly repairs, allowing for timely interventions.

Troubleshooting air valves often hinges on identifying the root cause of performance issues. Common problems include sticking valves due to dirt accumulation or misalignment. Industry studies suggest that proper installation—following manufacturer guidelines—can decrease the occurrence of these issues by up to 30%. Regularly updating valve systems to incorporate newer technologies can also improve reliability and reduce downtime.

Tip: Keep a detailed log of valve performance and maintenance activities. This documentation can assist in troubleshooting by providing a historical overview of potential recurring problems and their solutions.

Exploring the Unique Features and Applications of the Best Air Valves in Your Industry - Best Practices for Maintaining and Troubleshooting Air Valves

| Feature | Description | Application | Maintenance Tips |

|---|---|---|---|

| Pressure Regulation | Controls the downstream pressure of air systems | Used in pneumatic systems to ensure consistent operation | Regularly check pressure settings; inspect for leaks |

| Flow Control | Adjusts the speed of air flow in a system | Applicable in automation processes and equipment | Clean and lubricate moving parts regularly |

| Auto Drain | Automatically removes moisture from compressed air systems | Critical in preventing corrosion and maintaining efficiency | Inspect drain functionality frequently to avoid blockages |

| Solenoid Valves | Electrically controlled valves for precise operation | Commonly used in automated systems | Check electrical connections and clean components regularly |

| Isolation Valves | Used to shut off the flow of air for maintenance | Important in safety protocols and system isolation | Exercise valves periodically to prevent seizing |

Future Trends in Air Valve Design for Greener Industries

The landscape of air valve design is rapidly evolving as industries grapple with the pressing need for sustainability. According to a report by the International Air Valve Association, the global air valve market is projected to grow by 7% annually, driven by increasing regulations aimed at reducing greenhouse gas emissions. Advanced materials, such as lightweight composites and corrosion-resistant alloys, are becoming standard in valve manufacturing, minimizing waste and enhancing durability. Companies are now focusing on creating valves that not only optimize airflow but also reduce energy consumption significantly.

In addition to material advancements, smart technology integration is on the rise. The implementation of IoT sensors in air valves allows for real-time monitoring and automated adjustments, improving efficiency in manufacturing processes. A study by the Green Industry Council indicates that smart air valves can lead to energy savings of up to 30% in automated systems. This trend reflects a broader shift towards automation and data-driven decision-making in greener industrial practices, ensuring that companies are not only compliant with environmental standards but also enhancing operational efficiency.

Future Trends in Air Valve Design for Greener Industries

CLA-VAL UK Limited

Dainton House

Goods Station Road

Tunbridge Wells

Kent, TN1 2DR

© 2025 CLA-VAL UK | site map | Terms and Conditions of Sale and Warranty | Privacy policy